Made in the USA

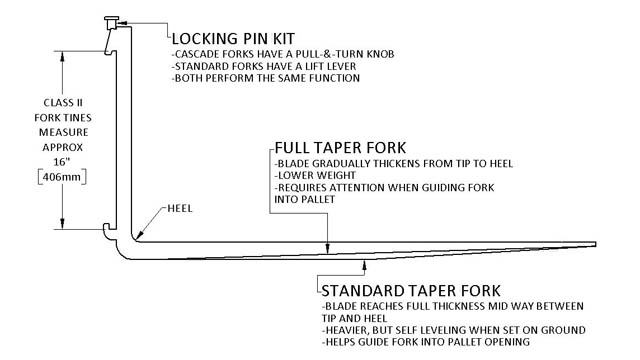

Artillian pallet fork sets use “fixed” fork tines. “Fixed” forks are captured by the carriage in two places, at the top and bottom of the tine. You can still slide the forks side-to-side, in and out from the middle of the frame but when the frame is tilted downward, the forks will remain attached to the frame. “Fixed” fork carriages normally have notches along the upper rail to lock the forks into the desired position.

Artillian pallet fork sets use “fixed” fork tines. “Fixed” forks are captured by the carriage in two places, at the top and bottom of the tine. You can still slide the forks side-to-side, in and out from the middle of the frame but when the frame is tilted downward, the forks will remain attached to the frame. “Fixed” fork carriages normally have notches along the upper rail to lock the forks into the desired position.

With this configuration, the forks can become a tool of many uses for a tractor, not just for moving pallets.

With the Artillian fork frame, the fork rails are made of a special very high strength and high wear resistant steel that is matched with the fork tine material to ensure many years of durable trouble free life.

Artillian doesn’t use “floating” forks due to their limited diversity. They are designed for mainly moving pallets quickly and efficiently. The forks are free to swing and remain level with the ground, making it easier to get the fork tines into the pallet openings without having to adjust the tilt angle as much as with fixed forks.

Artillian doesn’t use “floating” forks due to their limited diversity. They are designed for mainly moving pallets quickly and efficiently. The forks are free to swing and remain level with the ground, making it easier to get the fork tines into the pallet openings without having to adjust the tilt angle as much as with fixed forks.

Floating fork tines have a cylindrical sleeve at the top which couples to a round shaft on the fork carriage. This allows the forks to infinitely adjust side to side from the middle of the frame. However, the forks are usually free to slide unrestrained so they migrate when the tractor rolls across bumpy ground.

Also, floating forks have no ability to apply down pressure to the fork tines. Floating forks are generally not considered to be optimum for use on utility tractors.

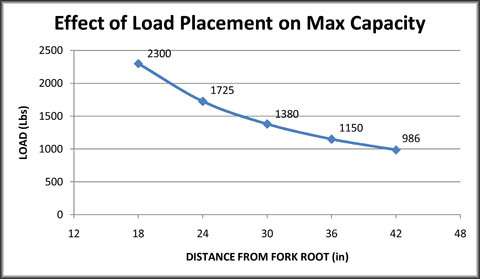

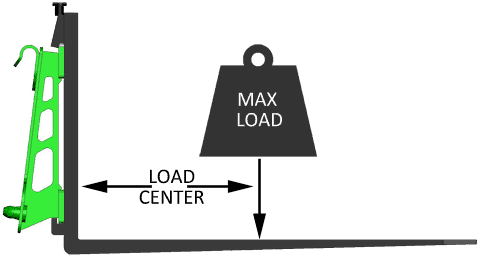

This graph illustrates how the lift capacity of a set of pallet forks changes as your load center moves out toward the tips of the tines. All brands of fork sets will behave similarly.

As the center of gravity of the load moves outward toward the tips of the forks, the lift capacity decreases.

Class II “Fixed Tine” Fork Tines measure 16″ (406mm) between the top and bottom mounting clips as shown above

The load capacity of a pair of fork tines is indicated as an amount of weight centered at a distance from the heel (bend) of the fork tine. This is referred to as the “load center”.

| Maximum Load of Fork Tines offered by Artillian | ||||

|---|---|---|---|---|

| MODEL # | DESCRIPTION | LENGTH | MAXIMUM LOAD | LOAD CENTER |

| FTC-484S | 48″ Cascade – Std Taper | 48″ (1220mm) | 3700lb (1680kg) | 24″ (450mm) |

| FTC-424S | 42″ Cascade – Std Taper | 42″ (1066mm) | ||

| FTC-423S | 42″ Standard | 2300lb (1045kg) | ||

| FTC-363S | 36″ Standard | 36″ (900mm) | ||

Professionally Engineered & Hand Crafted for Highest Efficiency

Our pallet fork frames employ high strength materials and high end modern manufacturing methods such as laser cutting, CNC machining, & durable powder coating. Bulk has been minimized which optimizes weight and visibility. All fork tines we offer are ITA compliant hammer forged Class II fixed fork tines which generally offer a safety factor of at least 3:1.

This is a great tool made by John Deere for estimating the amount of rear ballast needed on your 3pt hitch to counteract a load on your front-end loader.

**Requires Microsoft Excel or equivalent to open